Typical Analysis

How it works

5 small steps to realise first savings within 2 weeks.

1 / Discovery workshop

We conduct a discovery workshop with your team to determine the scope of a Proof of Concept (PoC).

2 / Setup PoC

With the information out of the discovery workshop, we will configure the analytic software according to your individual requirements.

3 / Run Analytics

We will demonstrate to you the software and how to execute the part analysis.

4 / Report walk-through

After the analysis is performed we will explain to you the results.

5 / Implementation

Our experts will support you in the implementation of the software, as well as possible part design modifications and production processes (in-house or through service providers).

Outcomes you can expect

1

Quick Automatic Screening Process

Using software, we help you analyze your parts and assemblies. Within minutes, you will get the results and access the complete technical and economic reports.

2

Technical Analysis

Our analysis recommends the best match of material, technology, and printer to 3D print the part. The results are according to your personalized preferences for different material properties.

3

Cost Analysis

The economic analysis comprises a cost comparison that easily presents the financial benefits between 3D printing and traditional manufacturing.

4

Customized Printing Configurations

The analysis allows you to choose your own configuration and display results based on them. You can choose from a printer library, your in-house printer, a specific material category, and more.

5

ROI Calculations

The reporting aggregates the overall cost with recommendations for your print projects.

6

ERP, MES, PLM integrations

Should you choose to continue using the software after the initial discovery project, we

can integrate it into any existing ERP, MES, and PLM software that you are using.

Project Advisory

Additive manufacturing is a game-changing driver of industry 4.0. However, many companies struggle to move past the testing and experimentation phases of 3D printing. At 3dpmaven, we help our clients unlock the full potential of additive manufacturing by partnering with them at every step, from strategy development to implementation and change management.

Additive Manufacturing Strategy

For manufacturing organizations to effectively embrace additive manufacturing technologies, it is critical to understand the challenges they face along such a digital transformation journey.

Implemented properly, additive manufacturing can significantly reduce material waste, reduce the amount of production steps, inventory being held, and reduce the number of distinct parts needed for an assembly. But one needs a strategy to make it work.

Before starting to commit any capital expenditure on the technology, it is critical to understand the benefits and to create a top-down corporate strategy that reflects areas where your manufacturing operation, end-use parts, and products can truly benefit.

Project Guidance

3D printing applications require a lot of know-how and resources. If you have the need for expert resources and planning in your project, we can help out with exactly that and support you with your project execution.

Field of Application

3D printing allows great design freedom and opens up interesting possibilities that are otherwise not possible. We would be happy to show you what is possible with the latest technology, so you can exploit the entire potential.

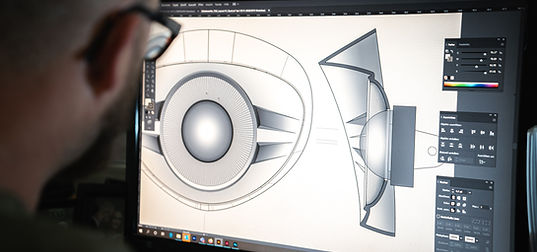

Design

Conventional design is very different from design for 3D printed components. We support you in 3D printing design and can show you tips and tricks to fully exploit the potential of 3D printing.

Technology & Material Selection

There are many technologies and materials available for 3D printing, all with their own advantages and disadvantages. We help you gain an overview and find the ideal solution for your application.

Depending on your selections we will guide you in regard to post-processing / finishing options for your application.

Sourcing

It can be very time-consuming and difficult to choose the right 3D printer from the masses. Thanks to our know-how of the industry, we can assist you in the procurement of a 3D printer. We can provide pre-purchase advisory services including comparison and considerations.

However, owning a printer is not the only option. We can guide you in preparing a business case with investment vs. producing parts on demand. This could include in-house design and outsourced printing to a service bureau.

Parametrization

Often the exact adjustment of a 3D printer takes a lot of time and can be frustrating without expert know-how. Besides the machine setup, we can also advise with considerations such as enough power, climate control, extraction, and many other facility-related aspects.

Change Management

Digitalization implies a lot more than the technical implementation of a new Industry 4.0 solution. It is a process that must also be driven and lived by the employees – and requires their expertise in existing workflows and processes. It is crucial that those involved understand the added value and, ideally, have a positive attitude toward digitalization.

Many managers with staff and shopfloor responsibility underestimate the importance of involving shopfloor staff at an early stage when introducing and using the optimal digitalization solution. Often, the focus of the project is on the technology itself.

Change management aims at ensuring the acceptance and, above all, the efficient use of such solutions. This includes involving stakeholders before, during, and after the project phase to ensure optimal implementation and long-term success.

3D Printing Service

With our growing network of 3D printing service providers, we can manufacture prototypes, spare parts, small series, and individual parts for you. Geometrically precise and functionally optimized.

Besides a growing geographical coverage, we offer polymer and metal 3D printing with processes such as FDM, SLA, MJF, and SLS - with further technologies being added constantly. This includes post-processing where needed.

Our online calculator offers features such as multi-3D file upload, process and material selection, and price quotation. Click here to upload your 3D data.